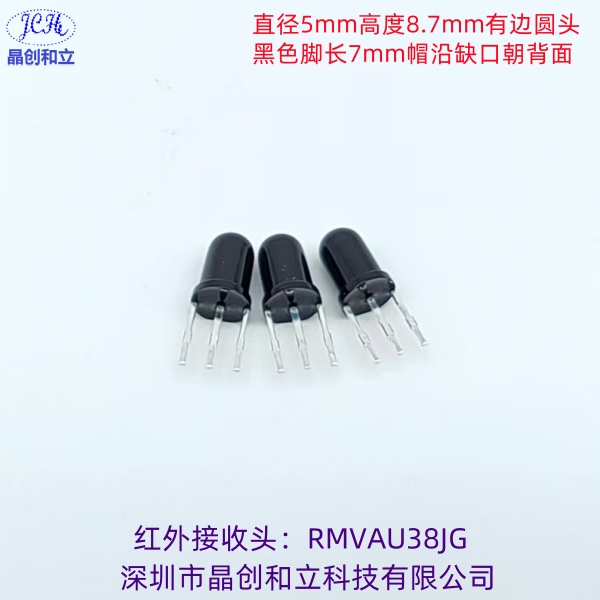

RMVAU38JG

晶创和立

黑色

圆头有边沿

940

5mm

企业名:深圳市晶创和立科技有限公司

类型:原厂制造商

电话:

0755-23210829

0755-23210829

0755-23210829

0755-23210829

手机:13632890460

13684976733

13360070460

13392150460

联系人:蒙 奎/孟凡然/刘石华/何玲

邮箱:mk0622@163.com

地址:广东深圳龙华区民治街道牛栏前港深国际中心9楼C913

RMVAU38JG焊接 Soldering

RMVAU38JG焊接过程中的不慎操作将会引起产品的损坏,请务必注意。焊接过程中应避免对产品支架或封装部分施加 压力。焊接时,请保证焊接位置与封装树脂底部有一定的距离,该距离因不同的焊接方法而有所不同,请 参照以下推荐焊接条件。

Damages may be caused during soldering,please be careful. Please note that don’t put stress on product bracket or package part when soldering.And make sure keep some distance from soldering joint to the bottom of epoxy package when soldering.The distance is determined by different soldering techniques,it’s recommended to take following soldering conditions as reference.

RMVAU38JG推荐焊接条件 Recommended Soldering Conditions

● 本产品不适合做回流焊接。It’s unsuitable for reflow soldering.

● 手工焊接只可焊接。Manually soldering should be done once only

● 器件外部温度在 40℃以下时,才可以对其进行处理。避免高温时操作对 LED 造成损伤。Please solder the LED under 40 degree to avoid high temperature damage the device

● 在焊接温度回到正常以前,必须避免使 LED 受到任何震动或外力 After soldering the LED ,please keep it out of any shake or outer force before it come to normal temperature

● 在焊接后推荐使用酒精进行清洗,在温度不高于 30℃的条件下持续 1 分钟,不高于 50℃的条件下持续 30 秒。使用 其他类似溶剂清洗前,请先确认使用的溶剂不会对 LED 的封装和环氧树脂部分造成损伤。It is recommended that to use alcohol clean LED after soldering.Cleaning should be done under 30℃ for 1 minute or 50℃ for 30 seconds.When using other solvents,please confirm whether the solvents would dissolve the package or resin beforehand .

RMVAU38JG注意:此一般指导原则并不适用于所有 PCB 设计和焊接设备的配置。具体工艺受到诸多因素的影响,请根据特定的 PCB 设计和焊接设备来确 定焊接方案。 Note:This general guideline may not suitable for all PCB designs or all soldering equipment configurations .The technique in practice is influenced by many factors.Please confirm soldering method by the PCB designs and configurations.

企业名:深圳市晶创和立科技有限公司

类型:原厂制造商

电话:

0755-23210829

0755-23210829

0755-23210829

0755-23210829

手机:13632890460

13684976733

13360070460

13392150460

联系人:蒙 奎/孟凡然/刘石华/何玲

邮箱:mk0622@163.com

地址:广东深圳龙华区民治街道牛栏前港深国际中心9楼C913